A Hard Start Wiring Diagram is a crucial schematic for anyone dealing with refrigeration or air conditioning systems. It illustrates the specific connections required to install a hard start kit, a device designed to overcome starting difficulties in compressors. Understanding this diagram ensures proper installation and reliable operation of your cooling equipment.

What is a Hard Start Wiring Diagram and How is it Used?

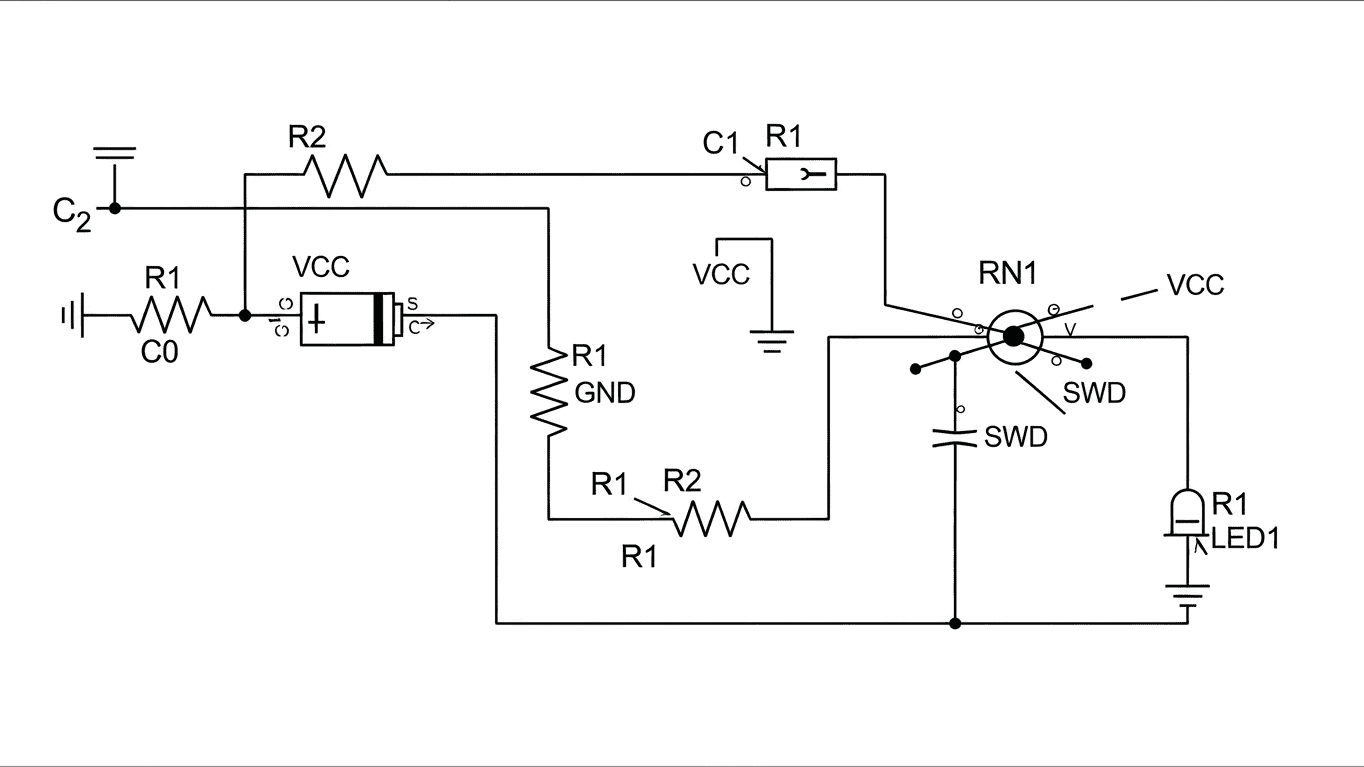

A Hard Start Wiring Diagram is essentially a blueprint that shows how to connect a hard start capacitor and potential relay (or electronic timer) to a single-phase compressor motor. These kits are employed when a compressor struggles to start due to low voltage, high head pressure, or simply age. The added components provide a temporary boost of power during the initial startup phase, helping the motor overcome initial resistance and begin running smoothly. The proper implementation of a Hard Start Wiring Diagram is vital for extending compressor life and preventing premature failure.

The basic function of a hard start kit involves a start capacitor and a potential relay. When the compressor calls for cooling, the thermostat sends a signal. The potential relay senses the voltage across the start winding and, if it's below a certain threshold (indicating difficulty starting), it connects the start capacitor into the circuit. This capacitor provides the extra torque needed to get the motor spinning. Once the motor reaches about 75% of its operating speed, the voltage across the start winding increases, causing the potential relay to disconnect the start capacitor. This prevents the capacitor from being overloaded and burning out. For those wanting to visualize this process, consider the following:

- Start Capacitor: Provides a phase shift and extra current for initial torque.

- Potential Relay: Acts as a switch, connecting and disconnecting the start capacitor.

- Compressor Motor: The component being assisted.

Different types of hard start kits exist, each with slight variations in their wiring. However, the fundamental principles remain the same. A typical Hard Start Wiring Diagram will clearly label the terminals for the main power supply (L1 and L2), the compressor's common, start, and run windings, and the connections for the start capacitor and potential relay. Understanding these labels and their corresponding connections is paramount. For clarity, here's a simplified overview of the components involved:

| Component | Function |

|---|---|

| Line (L1) | Hot wire from power source. |

| Neutral (L2) | Return path for power. |

| Common (C) | Shared terminal for start and run windings. |

| Start (S) | Start winding terminal. |

| Run (R) | Run winding terminal. |

Always refer to the specific Hard Start Wiring Diagram provided with your kit. Incorrect wiring can lead to damage to the compressor, the hard start kit, or even pose a safety hazard. Taking the time to understand the diagram and ensure all connections are secure and correct will save you time, money, and frustration in the long run.

For the most accurate and specific guidance on installing your hard start kit, please consult the detailed Hard Start Wiring Diagram that came with your purchased kit. This will ensure you have the correct schematic for your particular model and application.