Understanding the Gm Flex Fuel Sensor Wiring Diagram is crucial for anyone working with vehicles equipped with flex-fuel capabilities. This diagram provides a roadmap for how the sensor communicates with the vehicle's computer, ensuring optimal performance whether running on gasoline, ethanol, or a blend. A proper grasp of the Gm Flex Fuel Sensor Wiring Diagram can help diagnose issues and ensure correct installation or repair.

What is a Gm Flex Fuel Sensor Wiring Diagram and How It's Used

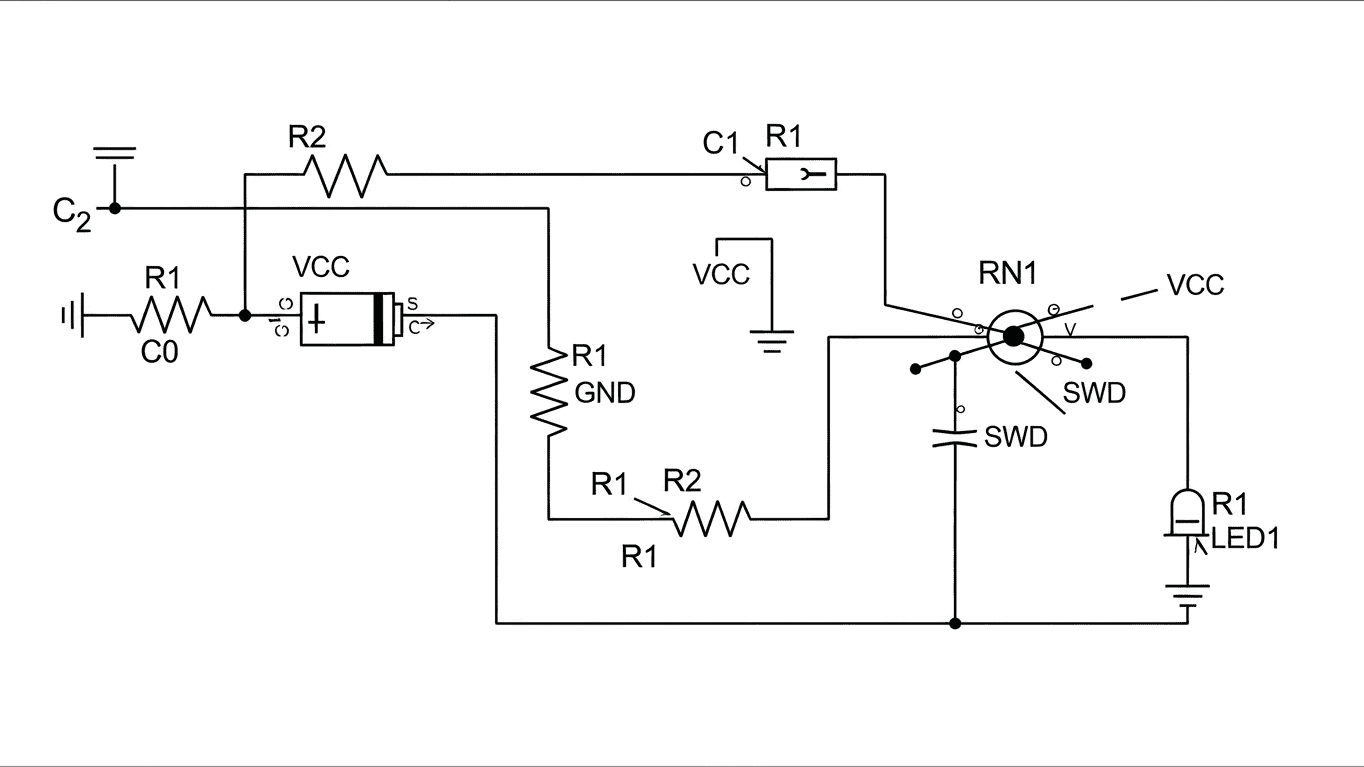

A Gm Flex Fuel Sensor Wiring Diagram is a schematic that illustrates the electrical connections between the flex fuel sensor, the vehicle's powertrain control module (PCM) or engine control module (ECM), and other relevant components. The flex fuel sensor itself is a vital part of the system. It detects the ratio of ethanol to gasoline in the fuel tank and sends this information to the PCM. This information is then used by the PCM to adjust engine parameters such as ignition timing and fuel injection pulse width. Without this sensor and its correct wiring, the PCM cannot accurately manage the engine's combustion process for different fuel blends, potentially leading to poor performance, reduced fuel economy, or even engine damage.

The wiring itself is typically straightforward, but understanding each wire's function is key. Most Gm flex fuel sensors have three to four wires. These wires usually include:

- A power supply wire (often 5 volts).

- A ground wire.

- A signal wire that transmits the ethanol content data to the PCM.

- Sometimes, an additional wire for signal conditioning or diagnostics.

The Gm Flex Fuel Sensor Wiring Diagram helps technicians and DIY enthusiasts trace these connections. They use it to:

- Verify correct installation: Ensure the sensor is wired exactly as specified by the manufacturer.

- Diagnose faults: If the flex fuel system is not working, the diagram helps pinpoint issues like broken wires, short circuits, or loose connections.

- Perform repairs: When a sensor or wiring harness needs replacement, the diagram serves as an accurate guide.

The importance of accurate wiring cannot be overstated; incorrect connections can prevent the flex fuel system from functioning at all or lead to erroneous readings that negatively impact engine operation.

Here's a simplified representation of typical connections, which would be detailed in a full Gm Flex Fuel Sensor Wiring Diagram:

| Wire Color/Function | Connection Point |

|---|---|

| Power (e.g., 5V) | PCM/ECM power output |

| Ground | Chassis ground or PCM/ECM ground |

| Signal | PCM/ECM dedicated input pin |

By consulting a specific Gm Flex Fuel Sensor Wiring Diagram for your vehicle's make, model, and year, you can ensure you have the precise information needed for any work on this system. Referencing the detailed diagrams available in your vehicle's service manual will provide the most accurate and comprehensive wiring information.

To ensure you have the most accurate information for your specific vehicle, please consult the detailed diagrams provided within your vehicle's official service manual.