Understanding the Gm 3-wire Crank Sensor Wiring Diagram is crucial for diagnosing and repairing many engine performance issues in General Motors vehicles. This diagram provides essential information about how the crankshaft position sensor, a vital component for engine timing, communicates with the vehicle's computer.

What is a Gm 3-wire Crank Sensor Wiring Diagram?

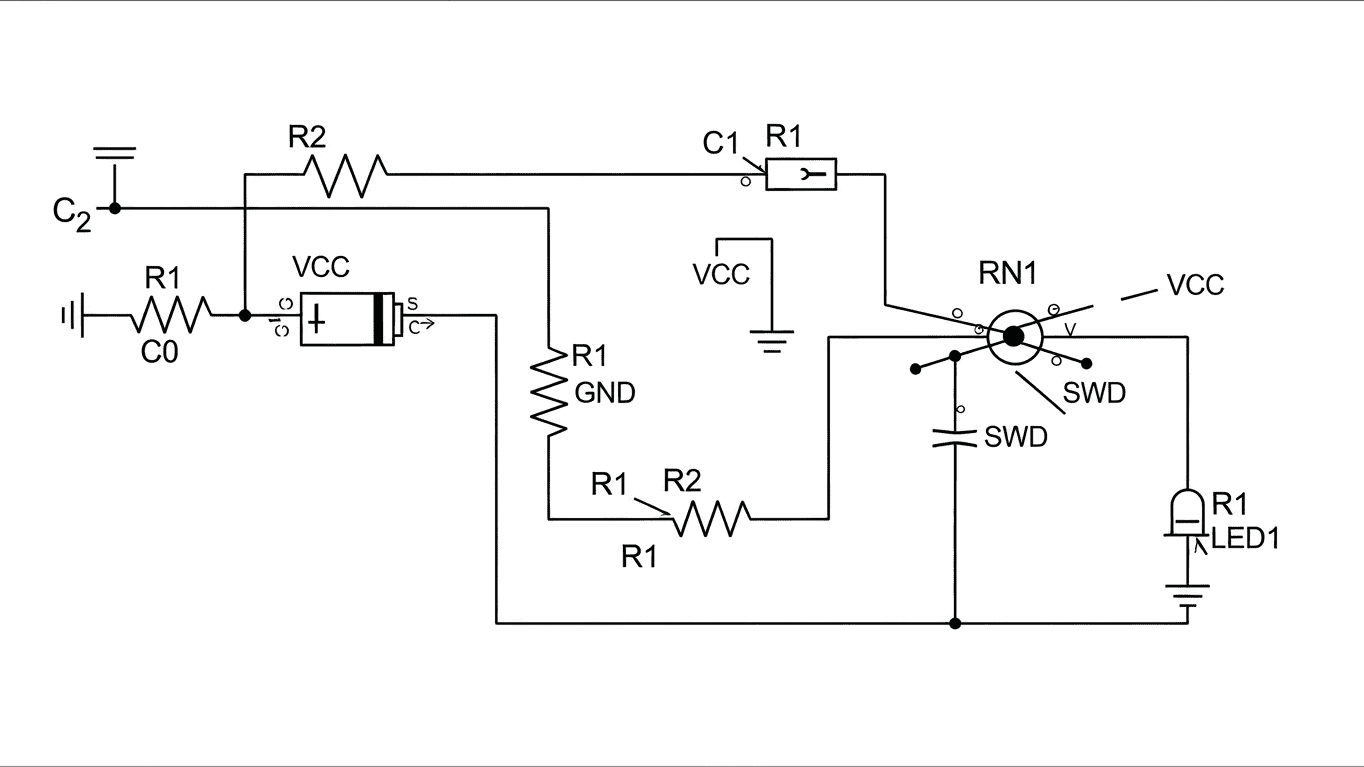

A Gm 3-wire Crank Sensor Wiring Diagram is a schematic that illustrates the electrical connections for the crankshaft position sensor (CKP) in a GM vehicle. This sensor plays a critical role in determining the exact position and speed of the engine's crankshaft. The engine control module (ECM) relies on this information to precisely time fuel injection and spark delivery, ensuring optimal engine operation. Without accurate data from the CKP sensor, the engine can exhibit a wide range of problems, from rough idling to complete failure to start. The accuracy of the Gm 3-wire Crank Sensor Wiring Diagram is paramount for effective troubleshooting.

These sensors typically have three wires, each with a specific function:

- Power (V+): This wire provides voltage from the ECM to power the sensor.

- Ground (GND): This wire connects the sensor to the vehicle's chassis ground.

- Signal: This wire transmits the sensor's output signal back to the ECM, which is usually a series of pulses that indicate the crankshaft's rotation.

Troubleshooting often involves using a multimeter or an oscilloscope to check each wire's function against the specifications found in the Gm 3-wire Crank Sensor Wiring Diagram. For example, a technician might perform the following checks:

- Verify that the power wire has the correct voltage when the ignition is on.

- Confirm that the ground wire has continuity to the chassis ground.

- Measure the signal wire's output as the engine cranks to ensure it's generating the expected pulses.

| Wire Color | Pin Location (ECM Connector) | Function |

|---|---|---|

| Red | B23 | 5V Reference Power |

| Black/White | C12 | Ground |

| Tan | D05 | Crankshaft Position Signal |

If you are working on a GM vehicle and need to understand the wiring for its crankshaft position sensor, meticulously reviewing the specific Gm 3-wire Crank Sensor Wiring Diagram for your vehicle's year, make, and model is the most reliable approach. The information provided in the sections that follow will guide you through this process.