Understanding a Forklift Battery Charger Wiring Diagram is crucial for anyone involved in the maintenance, operation, or troubleshooting of electric forklifts. This diagram serves as a roadmap, illustrating the intricate connections between the charger's components and the forklift's battery system. Properly interpreting this diagram ensures safe and efficient charging operations, preventing damage to both the equipment and the battery.

The Fundamentals of a Forklift Battery Charger Wiring Diagram

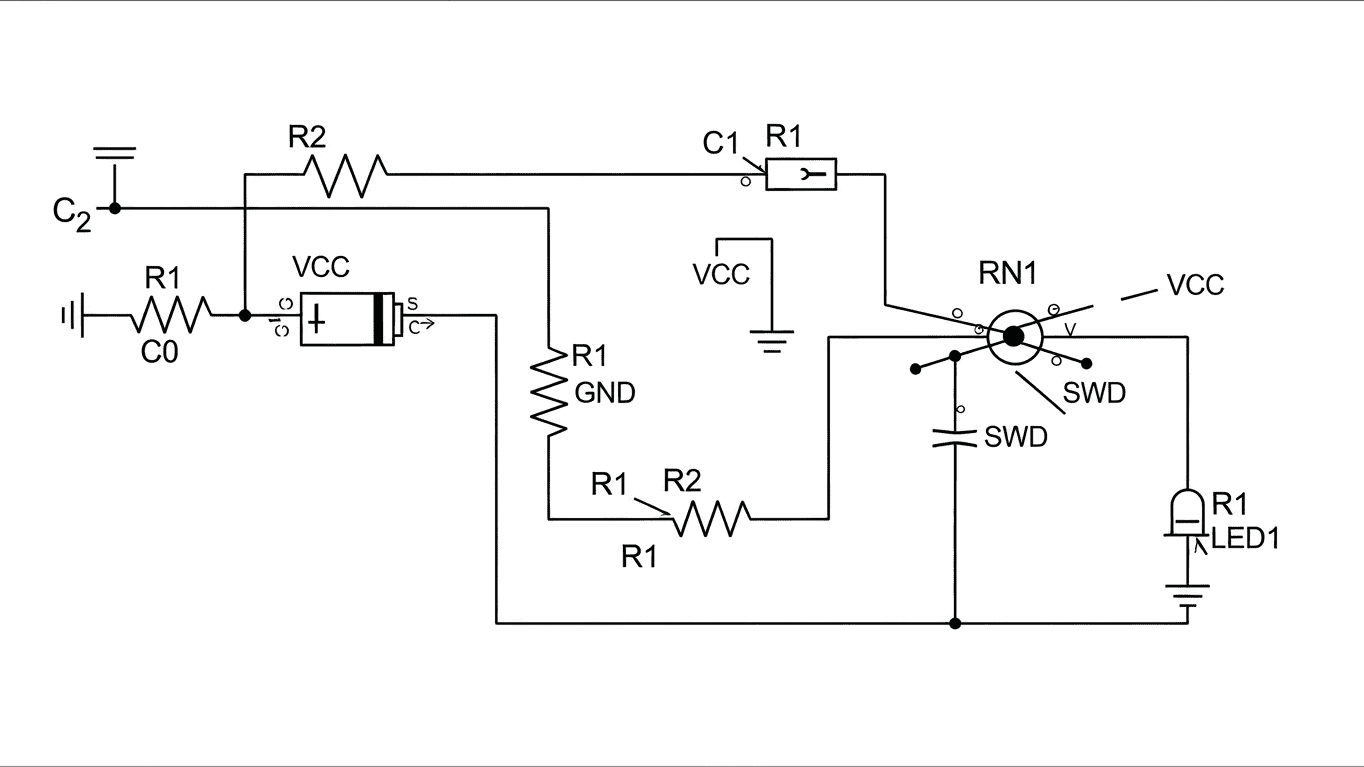

A Forklift Battery Charger Wiring Diagram is essentially a visual representation of how electrical current flows within a forklift battery charging system. It details the placement and connection of various electrical components, including transformers, rectifiers, control circuits, fuses, and connectors. Technicians use these diagrams to identify specific wires, understand voltage and current ratings, and trace the path of electricity from the power source to the battery. The importance of having an accurate and accessible Forklift Battery Charger Wiring Diagram cannot be overstated; it is vital for diagnostics, repairs, and preventative maintenance.

These diagrams are typically presented as schematic drawings, often color-coded for clarity. They depict symbols representing different electrical parts and lines indicating the wiring. For instance, you might see symbols for resistors, capacitors, and relays, each with specific markings. Understanding these symbols is the first step in deciphering the diagram. The complexity of the diagram can vary depending on the type of charger, but the core purpose remains the same: to provide a clear and unambiguous guide for electrical connections. The following elements are commonly found:

- Power Input Connections

- Transformer and Rectifier Assemblies

- Control and Monitoring Circuits

- Battery Connector and Polarity Indicators

- Safety Features like Fuses and Circuit Breakers

Proper use of a Forklift Battery Charger Wiring Diagram leads to several benefits. When a charger malfunctions, the diagram helps pinpoint the faulty component quickly, reducing downtime. It also aids in ensuring that the charger is correctly configured for the specific battery type and voltage, preventing overcharging or undercharging. This attention to detail protects the battery's lifespan and maintains the forklift's operational readiness. For example, a technician might refer to the diagram to confirm the correct connection of the positive and negative terminals to avoid damaging the battery. The diagram might also show a sequence of operations for the charging cycle:

- Initial Power-Up

- Battery Voltage Detection

- Charging Current Adjustment

- Charge Completion Signal

Here's a simplified view of what a section of a diagram might illustrate:

| Component Symbol | Description | Function |

|---|---|---|

| Transformer (T1) | Icon of a transformer | Steps down AC voltage from the mains |

| Rectifier (D1-D4) | Four diodes in a bridge configuration | Converts AC to pulsating DC |

| Fuse (F1) | A zigzag line with a circle | Protects against overcurrent |

To ensure you have the most accurate information for your specific forklift and charger model, always refer to the manufacturer's provided Forklift Battery Charger Wiring Diagram. Consulting the official documentation will guarantee that all procedures are followed correctly and safely.